Monday, May 31, 2010

2011 Audi A1

2011 Jaguar XF S First Look

2011 Lotus Elise Pictures

Saturday, May 29, 2010

Diesel Engine Combustion Efficiency

Author: gerald j ballmann

Subject: Diesel engine combustion efficiency.

1) What limits the compression ratio of a diesel engine?

2) What is the best fuel to use in a diesel engine for maximum efficiency?

Response #: 1 of 2

Author: daniel n koury jr

The compression ratio for a particular engine is limited by how strong the

engine block is. Too much pressure (compression) and something will break.

The best fuel will also depend on the design of the engine. But as a

general rule, the greater the energy content of the fuel, the greater the

efficiency (at least in terms of miles per gallon or km per liter). Water

has a low energy content and would not make a good fuel for example.

Response #: 2 of 2

Author: david r munoz

The limits to compression ratio are based on the knock limits of the fuel.

Knock is the term used to describe the auto ignition that occurs when a fuel

ignites because the pressure in the cylinder is such that combustion occurs.

In a spark ignited engine, it is best if the spark control the ignition,

since timing of the piston motion with the motion of the flame front is

critical to the operation of an efficient engine.

In a diesel engine, one relies on auto ignition of the fuel because the

engine is basically compression ignited (there is no spark plug). There-

fore, we want the fuel to be autoignited. However, some types of combustion

waves move faster than others. There are waves called detonation waves that

contribute to sonic velocities of the hot gases in the cylinder. It is

generally, the nonuniformity of the pressure within the cylinder that are

responsible for knock. Some believe that these nonuniformities are due to

detonation and others believe they are due simply to nonuniform combustion

or auto ignition in the cylinder.

The knock limits for a fuel are determined on a special single cylinder

engine called a CFR engine. On this engine, the compression ration can be

gradually changed. In general, a fuel is burned in the engine and the

compression ratio is changed high and low until the engine begins to shake.

This is known as the knock limit for the fuel. The higher the knock limit,

the higher the compression ratio.

How Diesel Engines work

Diesel Engine is a type of internal combustion engine (one from which work is obtained by compression of the fuel within the cylinders themselves) which operates on the constant pressure or diesel cycle principle. Fuel is admitted directly into the cylinder and combustion takes place as a result of the heat of compression.

In these engines, gas pressure in the cylinder acts on the piston, forcing it down during the power stroke to drive the crankshaft through connecting rods. The extreme positions reached by the piston correspond to the top and bottom dead center positions (TDC & BDC) of the crank and are so designated. The inside diameter of the cylinder is the bore. The distance traveled between dead centers (TDC &BDC) is the stroke, corresponding volume is the swept volume, or displacement, of the cylinder. The cylinder volume above piston when piston is at TDC is called clearance volume. Similarly the cylinder volume above piston when piston is at BDC is called cylinder volume. The ratio of the cylinder volume to the clearance volume is the nominal compression ratio.

The greater combustion pressure is the result of the higher compression ratio used by diesel engines. Compression ratio is a measure of how much the engine compresses the air inside the cylinder. In a diesel engine compression ratio ranges from 14:1to as high as 24:1 are commonly used. Higher compression ratios are possible because only air is compressed, and then the fuel is injected. This is one of the factors that allows the diesel engine to be so efficient.

Fuel Injector Testing

Mount he fuel injector in its test rig and connect up the oil supply. Under no circumstances should hands be placed under the injector spray. The high velocity oil jet can penetrate the skin and cause blood poisoning. With the injector priming valve open, operate the hand pump to prime the injector. Once the fuel flows from the priming valve it can be closed.

-

Oil Container

-

Pressure Gauge

-

Shut off valve

-

Pump lever

-

Test pump

-

Injector

-

High Pressure fuel pump

To test for the tightness between the nozzle needle and seat, operate the hand pump slowly to gradually increase the pressure until it is just below opening pressure. Maintain the pressure for a few seconds and ensure injector is not dripping.

To test for tightness between needle and guide, operate the hand pump to increase pressure until it is just below opening pressure. See how long it takes the pressure to fall off. If the pressure falls quickly the needle and guide should be replaced.

Where nozzles are cooled internally, these spaces should be pressure tested to check for tightness. Blank off one of the fuel valve cooling connections and fill the injector cooling space with water or fuel, depending upon the cooling medium. Then connect a low pressure air supply to the other connection. Leave the air on for a short period of time and test for internal or external leakage.

Measure Indicated Power in Diesel Engine with Indicator Diagram

The burning of fuel in an engine cylinder (2 stroke or 4 stroke diesel engine) will result in the production of power at an output shaft, some of the power produced in the cylinder will be used to drive the rotating masses of the engine.

Typical indicator diagram for a 2 stroke engine is shown in figure below. The area within the diagram represents the work done within the cylinder in one cycle.

The area can be measured by an instrument known as 'Planimeter' or by the use of the mid ordinates rule. [On modern engines this diagram can be continuously taken by employing two transducers, one pressure transducer in the combustion space and other transducer on the shaft. Through the computer we can thus get on line indicated diagram and power of all cylinders.]

The area is then divided by the length of the diagram in order to obtain mean height. This mean height, when multiplied by the spring scale of the indicator mechanism, gives the indicated mean effective pressures for the cylinder. The mean effective or average pressure [Pm] can now be used to determine the workdone in the cylinder.

Calculations

Area of the indicator diagram = a [mm2]

Average height of the diagram = a [mm2] / l [mm]

Average mean indicator pressure = a [mm2] / l [mm] x k [bar / mm]

or Pm = ( a / l ) x k [bar]

where k = spring scale in bar per mm

Work done in one cycle = Mean Indicated Pressure x Area of the Piston x Length of stroke

= [Pm] x [A] x [L]

To obtain the power of this unit, it is necessary to determine the rate at which work is done,

i.e. multiply work by number of power strokes in one second.

Now, Indicated Power of Unit [ip] =

Mean Indicated Pressure [Pm] x Area of Piston [A] x Length of Stroke [L] x Number of Power Strokes per Second [N]

or

Indicated Power of Unit = Pm L A N

Thursday, May 27, 2010

2010 Aston Martin Rapide Car

2010 Aston Martin Rapide Photo

2010 Aston Martin Rapide New Edition

2010 Aston Martin Rapide Interior

2010 Aston Martin Rapide Exotic Car

2010 Aston Martin Rapide Car Wallpaper

- Aston martin volante

- Aston martin v8 vantage roadster

2011 Volkswagen Polo GTI

2011 Volkswagen Polo V GTI Side View

2011 Volkswagen Polo V GTI Rear Angle View

2011 Volkswagen Polo V GTI Interior

2011 Volkswagen Polo V GTI Image

2011 Volkswagen Polo V GTI Front Angle View

2011 Volkswagen Polo V GTI Steering Wheel

- Volkswagen vw gti

- 2011 Volkswagen touareg

Friday, May 21, 2010

2011 Citroen DS3 R

2011 Citroen DS3 R Sport Car Series

2011 Citroen DS3 R Side View

2011 Citroen DS3 R Rear Angle View

2011 Citroen DS3 R Picture

2011 Citroen DS3 R Interior

2011 Citroen DS3 R Front Angle View

2011 Citroen DS3 R First Look

2011 Citroen DS3 R

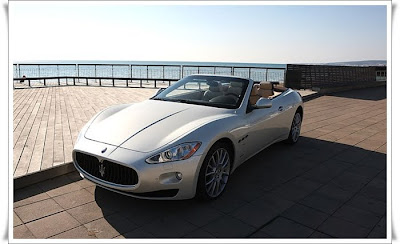

2011 Maserati Granturismo

2011 Maserati Granturismo Luxury Car

2011 Maserati Granturismo Gauges View

2011 Maserati Granturismo Exotic Sport Car

2011 Maserati Granturismo Convertible Side View

2011 Maserati Granturismo Convertible Rear View

2011 Maserati Granturismo Convertible Interior

2011 Maserati Granturismo Convertible Front View

2011 Maserati Granturismo Convertible First Look

2011 Maserati Granturismo Convertible Car Picture

2011 Maserati Granturismo Convertible Car Photo

Saturday, May 15, 2010

2011 Porsche Cayenne

2011 Porsche Cayenne Side View

2011 Porsche Cayenne Rear View

2011 Porsche Cayenne Front View

2011 Porsche Cayenne First Look

2011 Porsche Cayenne Car Wallpaper

2011 Porsche Cayenne Car Picture

2011 Porsche Cayenne Car Interior

.jpg)